Randive, Inc.’s commercial SCUBA divers support the Seaport Museum’s care of historic ships

A Seaport Museum Blog

by Jonathan Boulware, President and CEO

July 22, 2021

The Seaport Museum maintains a fleet of historic ships, each one constructed somewhat differently from the others. Much of the work to care for this fleet is performed by the Museum’s professional staff and volunteers. But from time to time we rely on expertise not represented in our team. Just recently, that was the outstanding team at Randive, Inc., experts at underwater repair.

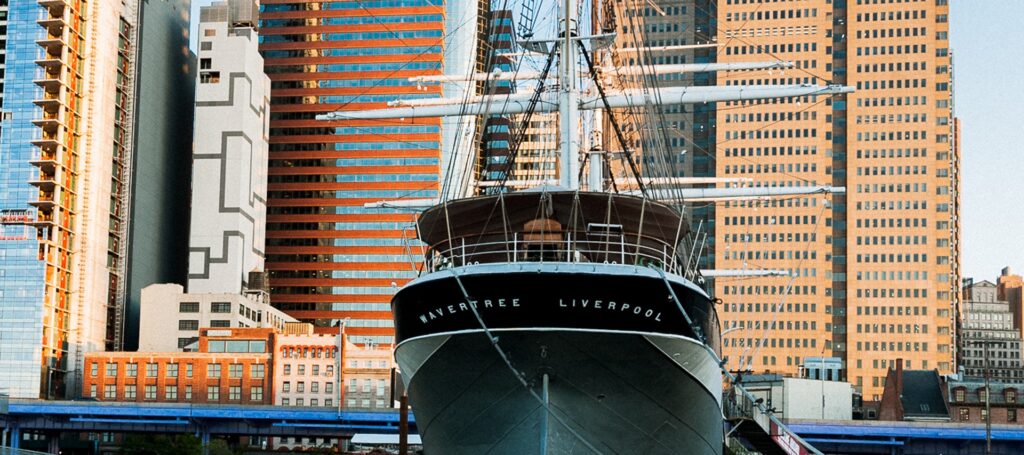

First, a note on construction. The tug W.O. Decker and schooner Lettie G. Howard are made of wood. The ship Wavertree is of riveted iron plates. The lightship Ambrose is of riveted steel plates. The schooner Pioneer was originally constructed of iron and is now a combination of iron and steel. Each of these vessels and their particular structure respond differently to the effects of salty water, freeze and thaw, impact, freshwater rain, and the many other things that affect floating objects.

Photo: Richard Bowditch

Wavertree‘s hull, in particular, is made of plates of 19th century wrought iron, lapped over each other and riveted to the frames (ribs) to form the “boat-shape” of her hull. At each of these plate-laps, held together by innumerable rivets, water can enter. That water, over time, will rust the iron itself and create pack-rust[1]Rust is seven times thicker than steel. When pack-rust forms between steel plates the steel plates are distorted by the pressure of the expanding rust in-between them, which can force the iron plates … Continue reading While a modern welded-steel ship has no actual gaps in the hull, a ship like Wavertree (or the lightship Ambrose) has these plate-laps that present particular challenges.

For large repair projects, a big ship like Wavertree is removed from the water in a floating drydock or graving dock. But from time to time, issues arise that require prompt attention but are too small to justify the huge expense of a docking. One of these arose just recently, and we thought this would be a good opportunity to highlight the specialized care and maintenance the Seaport Museum performs on its ships along with one particular skilled trade, represented here by the outstanding Randive, Inc., that has no equal.

Last month, during routine inspection, Wavertree‘s shipkeeper observed water seeping into the ship on the port side by way of a plate-lap that had last been repaired with a weld, likely in South America more than five decades ago. This lap was in adequate condition during Wavertree‘s last drydocking in 2016, so clearly something had changed recently. The likeliest culprit was the changing plate positions related to corrosion; the pack rust between laps created sufficient force to separate a weld and water began to seep into the ship. This isn’t what we want, of course, but it is normal. All historic ships “make water” in some way, either regularly as with the planked wooden vessels or through the propeller shaft gland where that shaft exits the hull, or occasionally as in this circumstance.

So what do we do when a ship like Wavertree has a small leak below the waterline? As noted, drydocking is overkill, like general anesthesia for a few stitches.

Instead, we took immediate steps to slow the water. This was a simple exercise in filling the affected area with packing material. In this case: cotton. Socks. Yes, ship preservation can be a low-tech business.

Then we called in our friends at Randive, Inc., which provides quality diving services to the largest shipping companies in the world and most of the marine related companies along the East Coast. They can do it all. Wearing commercial diving drysuits and special helmets or masks that allow for underwater repair work, the divers entered the water on Wavertree‘s port side.

Guided by marks on the ship’s hull established by the Museum’s waterfront crew, the divers quickly located the area.

First they cleaned it for inspection, and the packing was removed internally. This revealed the affected area both internally and externally. Water again began to enter the ship, but with the inside and outside exposed it was possible to clearly locate the trouble.

Using a special underwater two-part epoxy, the divers were able to make a solid repair. This repair will last years, certainly until the ship’s next drydocking.

Historically, divers have worked behind-the-scenes to keep the maritime industry afloat. With the invention of individual diving suits in the 17th century and improvements made upon them in the early 18th century, divers have been helping in ports around the world with ship husbandry, salvaging, and collecting sea food. People who took on diving jobs needed to be knowledgeable in ship repairs, able-bodied enough to stay underwater for long periods, and confident in their abilities as well as their tools to work with limited light.

The Museum’s collection includes a few artifacts related to diving in New York Harbor, including this early 20th century postcard, an early 20th century one-piece diving suit and gloves, and a late 19th century/early 20th century hand-crank dive pump that would supply air to divers as they worked below the surface.

This postcard is particularly interesting as it shows in the background the sign for Merritt & Chapman Derrick & Wrecking Company[2] The records of the Merritt-Chapman & Scott Corporation are held at G. W. Blunt White Library, Mystic Seaport Museum., a New-York based salvage and wrecking firm.

“New York harbor salvage diver,” ca. 1910, Wendell Lorang Maritime Postcard Collection, South Street Seaport Museum Archives 2005.051

This air pump was also made by New York business, A. Schrader’s Son. It opens from the top with a hinged lid. Box face has a circular metal cover for the gauge, and one one side there is a hand crank. A. Schrader’s Son was founded in 1844 by German immigrant mechanic August Schrader, and has its humble roots beginning in a small machine shop in Manhattan.

Initially, Schrader developed supply fittings and valves for rubber products like air pillows and life preservers. But his inventive nature and strong interest in diving eventually led him to design and manufacture improved diving helmets and air pumps, catapulting the young company into more than 50 years of successes in the dive equipment business.

By 1890, having brought his son, George Schrader, into the business, the senior Schrader’s attention turned to bicycles – specifically the newly popular pneumatic tires. During this time, Schrader and his son developed what would become the company’s most popular and famous invention – the Schrader pneumatic tire valve − the very same valve that is used on most motor vehicles and bicycles in the world today.

[Wood box containing an air pump] early 20th century. Gift of Harold Fallick. South Street Seaport Museum 1991.080.0001

Commercial diving opened the doors for engineering, marine exploration, and general upkeep of both ships and the docks they pulled into. Although divers work out of sight, their impact on the Port of New York and its structures has been appreciated by everyone on shore.

For more than five decades, the Seaport Museum has cared for a fleet of historic ships. Over the past ten years, we’ve gone through most of the fleet, including the award-winning restoration of Wavertree in 2015-2016, huge amounts of work on our two schooners and tugboat, and the upcoming restoration of the lightship Ambrose. The fleet is in remarkable condition now, and we’re focused on routine maintenance and activation of these vessels. But from time to time, we need to call in further expertise. And when we do, we call experts like Randive, Inc. This Wavertree project was the most recent Randive, Inc. engagement, but they’ve dived on schooner Lettie G. Howard for propeller changes, on lightship Ambrose, barque Peking, ship Wavertree, barge Progress, and Pioneer’s floating dock for anode maintenance. They’ve probably seen the underside of every one of our ships in the current and past fleets.

The Seaport Museum thanks our friends at Randive, Inc. for their rapid response for the care they showed in assisting the Museum in one of its most important tasks. They are among the broad efforts that keep the Seaport Museum alive and help us to tell the story of Where New York Begins.

Wavertree Open Days

Join us from for tours of our historic ships and more.

References

| ↑1 | Rust is seven times thicker than steel. When pack-rust forms between steel plates the steel plates are distorted by the pressure of the expanding rust in-between them, which can force the iron plates to shift or move away from each other. |

|---|---|

| ↑2 | The records of the Merritt-Chapman & Scott Corporation are held at G. W. Blunt White Library, Mystic Seaport Museum. |